Knowledge Center

This page is dedicated to educating our customers about various products, services, and finishes we offer.

Slide Lightening

As if you need more of a reason than looking awesome, the main idea behind lightening the slide is to reduce moving mass. A lighter slide will track faster and therefore get you back on target faster for quicker follow up shots. There is a lot of misinformation out there about slide lightening making your slide weaker, etc. While that could certainly be the case if someone removed too much material from the wrong areas - it's far form the case with our slide cuts. The fact of the matter is out of thousands of slides we have milled, only ONE has cracked. It was a prototype slide of a new cut. We addressed the issue, and that cut has now been done on hundreds of slides now with zero reports of issues.

Optic Milling

So you're on the fence about putting an optic on your pistol? Or maybe you know you want to do it but you're thinking of using a dovetail mount instead?

First, let's cover why someone would want an optic on their pistol in the first place. For many of our customers, it's aging eyes getting the best of them. They just can't focus on iron sights like they used to and it's hindering their shooting. A red dot is the answer for them. For other shooters they simply want to be able to shoot faster and more accurately. While there is a learning curve to shooting a slide mounted optic, you will simply never shoot faster or more accurately with iron sights than you can with a red dot IF you're willing to get over that learning curve.

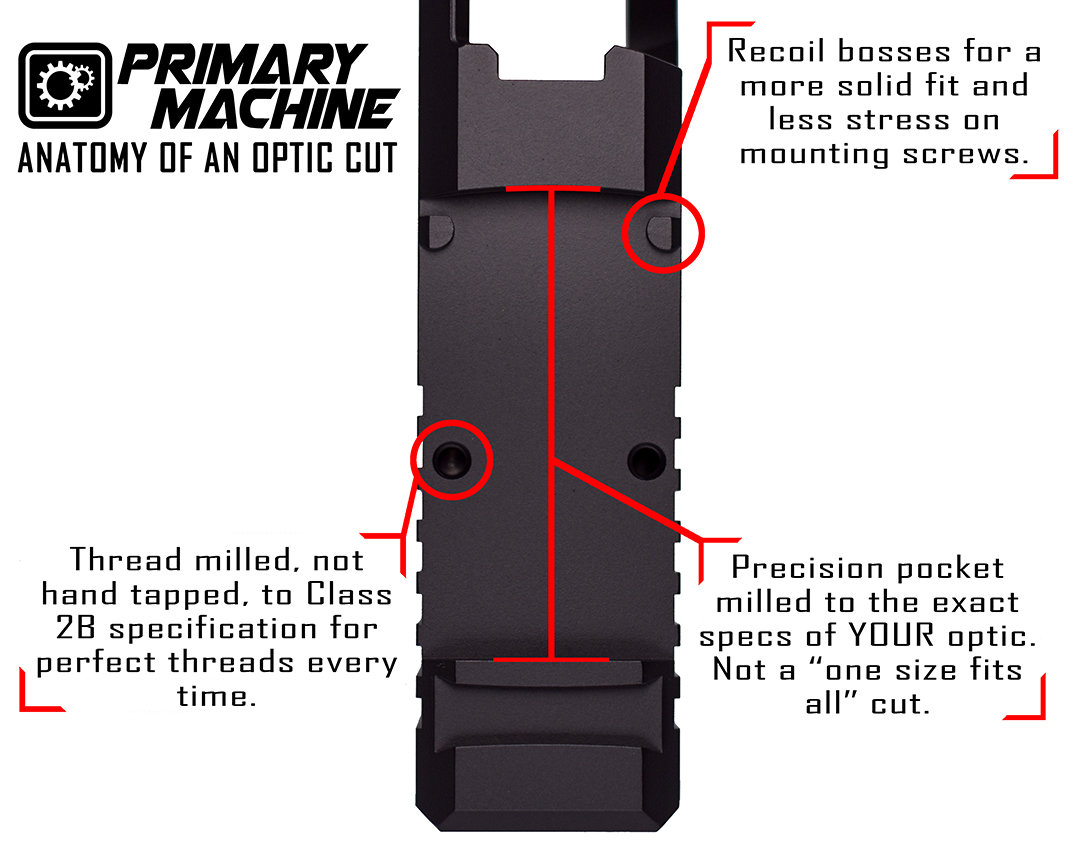

So why get your slide milled vs using a dovetail mount? Many reasons. Not only does it look much better and cleaner, the optic will have considerably more support being in a pocket on the slide. A dovetail mount will only offer support on the mounting screws and recoil bosses whereas a milled slide will also offer support in front and behind the optic. If that isn't enough reason, having the dot lower to the bore axis also makes hold overs and unders considerably less dramatic than a dovetail mount which will place the optic much higher over the bore.

Stealth Comp

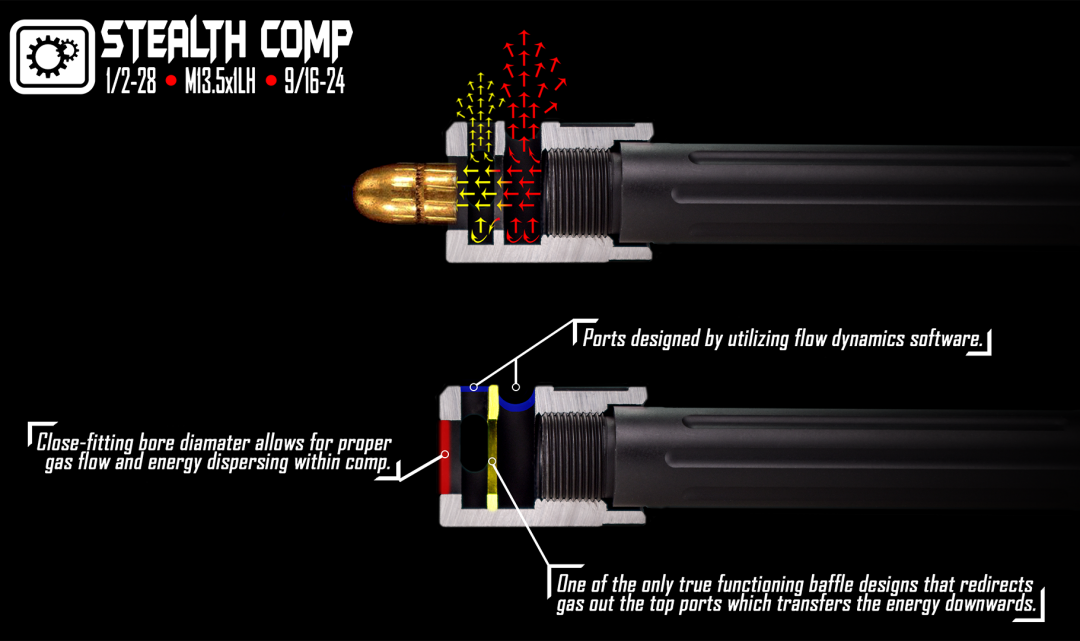

The idea behind a comp is simple. Make the gun shoot flatter by directing expanding gas upwards to get back on target quicker. And our comp does a very good job of doing just that. This is how it works:

Cerakote

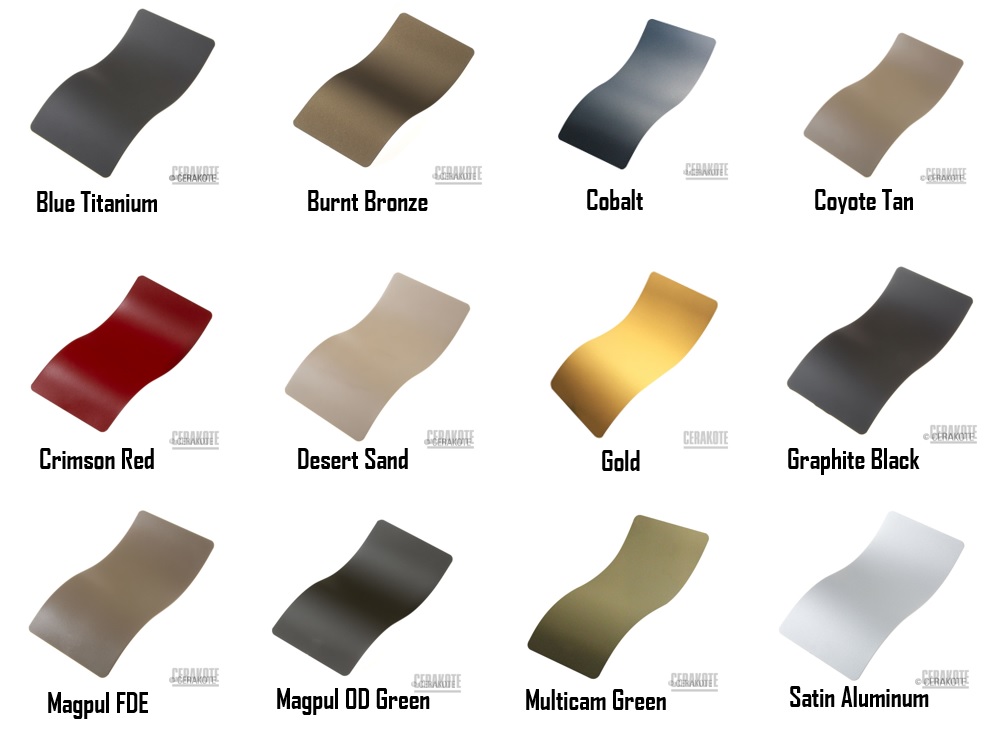

Cerakote is the leader in aftermarket firearm finishes and is also becoming extremely popular as an OEM finish. Cerakote offers just about every color you could want and the list of reasons why you would want it on your firearm is a mile long. Click here to see all of the testing done on Cerakote and why we choose to use it for our finishing: https://www.cerakoteguncoatings.com/testing/

Black Nitride

So you just want to go back with a black finish? Black nitride is what you're after. While it is slightly less corrosion resistant than cerakote, it is considerably more durable. We trust you know the importance of keeping a bit of oil on your firearm, so corrosion is a non issue. We use the most highly regarded and highly recommended black nitride QPQ processor in the country. Black nitride offers a hardness of HRC 55 - 70. This is harder than most hardened steel alloys. It is a very rich, black finish with great lubricity features.

Anodizing

All of our aluminum products are Type III class 2 hard anodized. Anodizing offers a very smooth, even finish and more importantly, it's extremely hard. How hard is it? It's right up in surface hardness with diamonds and sapphires.